Learn more about how to achieve and manage a green supply chain.

In the rural areas of Quebec, Canadian company Valorix faced a significant challenge managing the collection and disposal of organic waste. Each year, 58%, or 35.5 million tons, of all the food produced in Canada is wasted. This waste costs the economy over $49.5 billion and has a significant environmental impact through CO2 and methane emissions.

InnovLOG, the Quebec Institute for Innovation in Logistics, stepped in to offer a solution. It is a non-profit organization within the only college center for technology transfer (CCTT) recognized by the Quebec government. The institute has broad expertise in digital transformation, supply chain management, and green logistics.

InnovLOG faced a major challenge in waste management logistics. The team needed to improve the collection and disposal of organic waste, which is crucial for environmental sustainability and economic vitality.

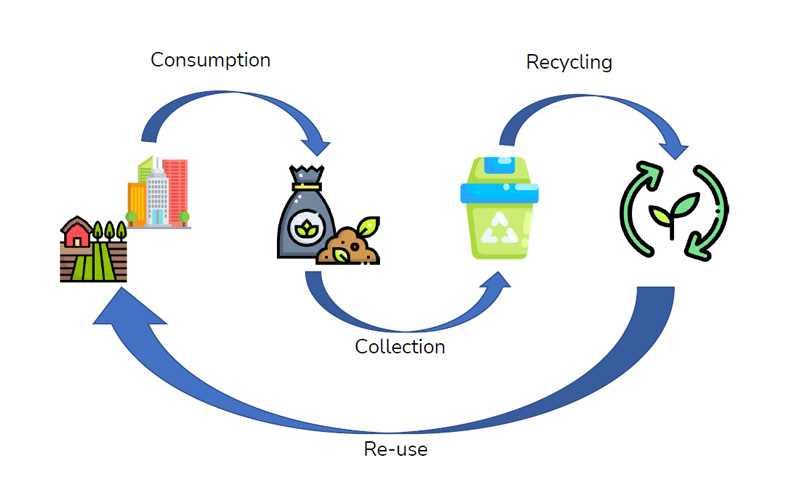

A circular economy model proposed in waste management logistics

Collecting organic waste involves various stakeholders, including waste generators, collection companies, and processing facilities. For that reason, it is necessary to have strong coordination for success. The complexity of this process extends to the need for specific, costly equipment like collection vehicles, essential for managing the quick decay of waste. Moreover, factors like weather and traffic intensify these challenges, impacting the speed and efficiency of the transport process.

To address these challenges, InnovLOG decided to optimize Valorix's organic waste collection, focusing on reducing operating costs and environmental impact. A key challenge was to optimize routes and schedules for vehicles in logistics. Optimization of waste collection had to include selecting the right vehicle for each type of operation to minimize CO2 emissions and costs, as well as improve the client's efficiency.

For this waste management logistics project, InnovLOG adopted a five-step methodology, starting with precisely defining the problem. They identified the key challenges in organic waste collection and local needs, gaining insights from visits to each value chain actor. To gather essential data, InnovLOG used client databases and surveys for detailed information from value chain actors.

Then the team created a waste logistics model based on key assumptions: each bin generated waste at its own rate, and every waste collection vehicle had to return to the depot after completing all tasks.

InnovLOG's primary goal was to reduce total vehicle and emission costs. They ensured each waste bin was collected once by a vehicle and that the quantity of bins per path stayed within the vehicle's maximum load capacity. At the same time, they managed to keep the total route length within a predefined maximum through logistics route optimization.

Given the project's complexity, InnovLOG needed a powerful yet user-friendly solution. As a result, they chose anyLogistix, a software that uses advanced algorithms to optimize logistics operations. This choice provided a balance between sophisticated logistics route optimization and ease of integration, avoiding the complexities of coding and mathematical modeling.

anyLogistix vs. modeling with coding

For this unique case, InnovLOG used the Transportation Optimization (TO) experiment in anyLogistix, which is important for route optimization in logistics.

Initially, they imported data, including the location of the depot and each waste bin and information about the waste generation rates at each collection point. This data structure was crucial for setting up their Capacitated Vehicle Routing Problem experiment within anyLogistix. The experiment's setup involved defining parameters and constraints, like vehicle capacity and time windows for collection. The last step was executing the experiment to solve Valorix's vehicle routing problem.

Performing the TO experiment in the waste management logistics project (click to enlarge)

To resolve the challenge, the practical application involved a distribution center, 42 pick-up sites, and 10 specialized 5-ton trucks operating over a 7-day period. The collection could occur between 8 a.m. and 5 p.m., with the depot's operating hours being from 6 a.m. to 7 p.m. InnovLOG meticulously planned each route's start and end times through route optimization to ensure operational efficiency and cost-effectiveness.

Transportation optimization results (click to enlarge)

As a result, the team identified optimal routes for waste collection, significantly minimizing transport costs and CO2 emissions. By implementing anyLogistix, InnovLOG has improved the efficiency and profitability of Valorix, a waste management logistics company. The project not only enhanced economic and environmental performance but also strengthened the company's commitment to corporate social responsibility. Furthermore, it improved the client's public image and long-term financial sustainability.

This project showcased InnovLOG's expertise in using advanced analytical tools for route optimization in logistics. By selecting anyLogistix, the team could efficiently address their client's needs, ensuring that all operational and environmental constraints were met. The successful implementation of this solution not only validated InnovLOG's methodical approach but also its commitment to using technology for sustainable and cost-effective logistics solutions.

Learn more about how to achieve and manage a green supply chain.

This case study was presented by Othmane Dayi and Ahmed Ben Dahmen from InnovLOG at the anyLogistix Conference 2023.

The slides are available as a PDF.