Read more about the most popular techniques that aid logistics planning.

Logistics planning and strategy is crucial to the success of your organization. Business owners who don’t plan their logistics run the risk of expensive disruptions, inefficiencies, and an inability to scale their operations successfully, especially during difficult economic times.

Contents:

In logistics planning, a type of logistics management, a company owner plans how to deliver the right good to the right client at the right time and for the best price. Building a lean, cost-effective logistics operation that can maintain service levels at all times and survive supply chain interruptions is the aim of planning logistics.

Like any strategy or alternative plan, it aids in safeguarding your company from unforeseen difficulties. Beyond future-proofing, however, logistics planning may enhance daily business operations and place you in a position to succeed both now and in the future.

Planning for logistics is a constant optimization process that demands regular time and focus.

The following are some logistics-related tasks that organizations should prepare for:

Read more about the most popular techniques that aid logistics planning.

Traditionally, logistics planning is carried out at a variety of levels, including:

The advantages of a logistics plan are numerous. Planning logistics aids in achieving short-term objectives and paves the way for long-term objectives. It also enables businesses to meet customer demand more quickly by increasing supply chain efficiency and lowering supply chain expenses through optimization. A robust, well-executed plan can boost a company's income because it will reduce costs and promote client loyalty.

Logistics planning helps businesses reduce risk in an evolving landscape by helping them to foresee change and create plans to adapt to it. Because supply chains are constantly changing, many businesses create logistics strategies for particular product lines, geographical areas, or customer segments. This allows them to respond to market changes that affect one region or line of business while preserving efficiency across other business lines.

Planning for logistics is a dynamic process that is always changing. While unforeseen events cannot be taken into account, planned actions, in particular, can. The following are some examples of both:

Planned disruptions:

Unplanned disruptions:

These can be handled successfully, even when they come as a surprise or shock if your logistics plan and strategy have been carefully thought out.

By creating a resilient supply chain through logistics planning now, you won't have to worry as much about chance events or unforeseen difficulties causing your company to falter in the future.

Often overlooked, but crucial to successfully planning logistics, is reverse logistics. This is particularly relevant in e-commerce. Reverse logistics is largely used when a customer returns goods. Customers choose to return items for a variety of reasons, so offering them a simple option to do so is essential if you want to remain competitive.

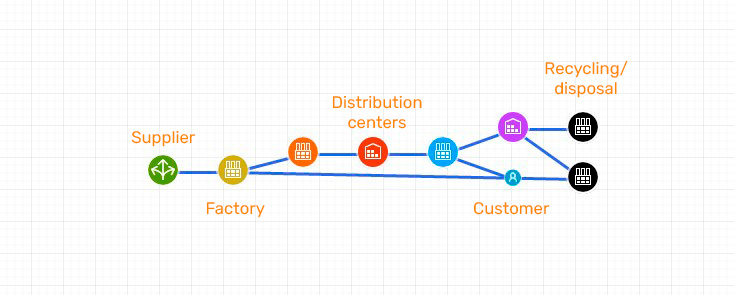

Reverse logistics diagram in anyLogistix supply chain design software

Your logistics plan should outline your returns policy and procedure and suggest strategies to reduce return costs. You should specify the conditions that must be met in order for a return to be considered legitimate. These include:

You should preferably have a strategy in place for reducing the number of returns requests your company receives.

Logistics planning is a tactical supply chain requirement. However, what helps or enables this is another concept that is logistics network planning. And this is the strategic requirement. It assists in establishing the most effective approach to create, manufacture, and deliver goods and services to clients at a specific level while preserving a predetermined profitability threshold.

This scientific approach takes into account the costs and trade-offs related to transportation, inventory, warehousing, and location in order to achieve predetermined goals.

To construct the most effective supply chain network possible, network planning works in tandem with network design and network optimization. This ensures that consumers are satisfied, and businesses are profitable.

Building all the restrictions and variables into a single dynamic business plan is the key component in any logistics planning and network design strategy. In order to do this effectively, optimization and simulation can be used. These are the most common techniques for solving complex supply chain problems.

Read our white paper to find out more about these tools.

download