Sales and operations planning is an integrated business management process that helps to align supply chain operations and business strategies with consumer demand. This mid-term tactical planning gathers all the business plans – sales, marketing, new product development, manufacturing, purchasing, and finance – into a single cluster.

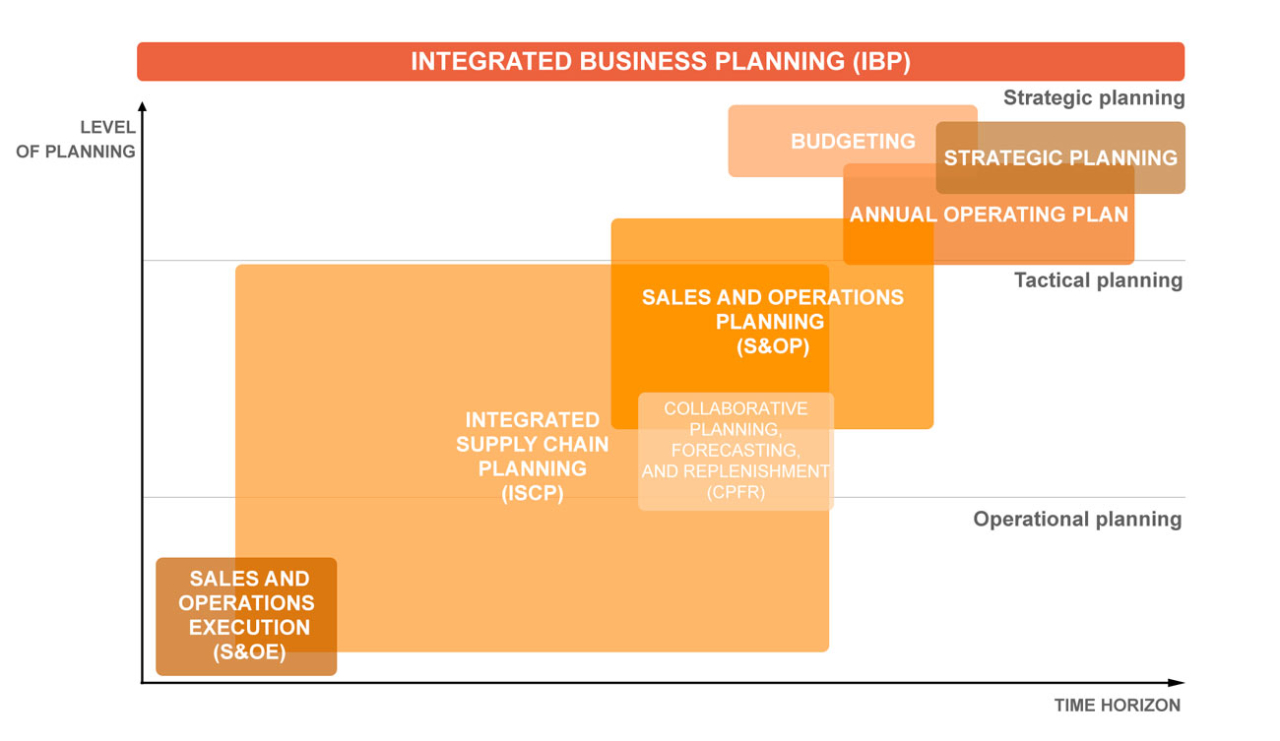

Sales and operations planning as a part of the integrated business planning process

It is essential that different departments of a business communicate and collaborate to provide timely, required information for supply, production, and demand planning and for delivering all orders on time, in full, and at the minimum cost.

Overall, S&OP helps supply chain stakeholders anticipate and manage changes quickly, reducing supply chain disruptions and improving customer satisfaction.

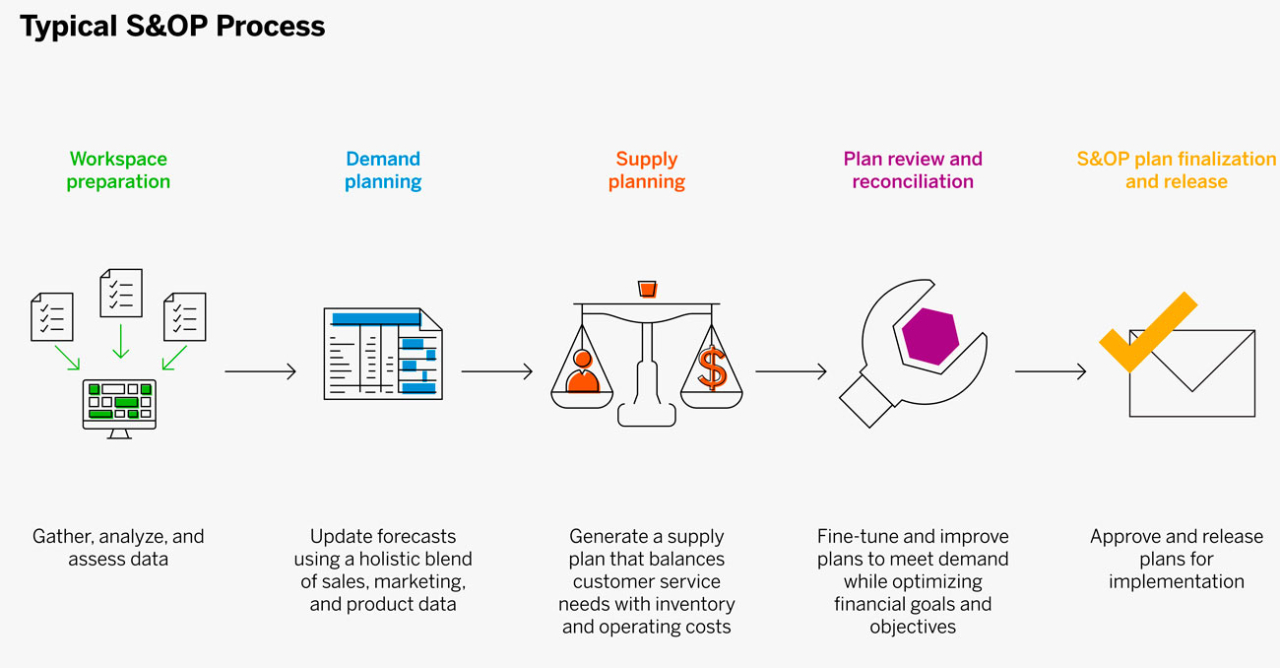

How the sales and operations planning process unfolds may differ depending on the needs and dynamics of each organization, nevertheless, the overall steps tend to be the following:

Typical sales and operations planning process. Source: SAP

The key stages in this process are demand planning, supply planning, and plan review. Let’s explore them in more detail.

Demand Planning

For a supply chain to be effective, it must focus on demand, meaning on a customer or a client. A demand forecast should answer the question "how many units of a certain product can be sold in a certain region at a certain price" rather than "how many products can our company deliver". Therefore, such forecasts should be made by sales representatives and marketers, rather than by production, finance, and logistics people. Demand planning in the S&OP goes through several phases.

First, a Base Demand Forecast is created based on historical sales data and using forecasting algorithms.

Then, planners edit it and add information that the forecasting algorithms might’ve left out, including details about marketing promotions, actions that the competitors took that may affect the demand, and other significant factors.

Lastly, stakeholders from other departments discuss, approve, and unify the demand forecast which is then used for further planning.

At the end of the day, this demand forecast considers only market needs and does not consider the company's ability to meet that demand (the company's supply chain constraints). It is therefore also called an Unconstrained Forecast. Production, raw material, storage, transportation, financial, and other constraints can be added later in a supply chain model.

Supply Planning

Supply planning is the process of determining how much inventory is required to meet the demand. The result is a supply plan that balances the demand with the available resources, such as raw materials, production capacity, and distribution capabilities.

Ultimately, the main goal of supply planning is to ensure that the organization has the right amount of inventory to satisfy customer demand while avoiding inventory shortages or excesses.

In order to create a supply plan where all inventory, production, and distribution processes are considered, supply chain managers use optimization and simulation modeling approaches.

Plan Review

Following the development of demand and supply plans, the decision-makers from every functional area within the organization as a team evaluate the plans using analysis and simulation tools in order to refine and enhance them.

Modern supply chains produce a ton of data and are exposed to various risks. As a result, analyzing them becomes more complicated, and dynamic simulation modeling becomes the preferred option.

Simulation can be used to:

This is the point where all stakeholders agree on what needs to be improved to make the most of the resources available, meet demand, and achieve financial goals.

It is essential to understand the purpose of S&OP as a part of the integrated planning process. It is not to reduce supply chain costs but to balance all KPIs and flexibly manage cross-functional processes such as purchasing, logistics, production, and sales. Ultimately, the goal is to improve the overall efficiency and profit of the company.

Initially, companies can plan in Excel. Later, when tables become complex, difficult to maintain, and highly error-prone, there is a need for a designated tool — a platform that forms a unified information environment for the stakeholders. However, such a transition indicates that the company has reached a certain level of maturity.

To help supply chain and logistics leaders assess their logistics maturity, Gartner have developed five planning stages:

Stage 1: React

Departments make plans independently of each other, without considering supply chain constraints. There is no cross-divisional standardization of the logistics services offered to customers and little coordination. The focus is on maintaining the continuity of the core processes.

Stage 2: Anticipate

Logistics activity and performance are captured and reported using an organization-wide model, enabling better anticipation of demand. The company utilizes standard approaches to demand planning. These include, for example, sales planning based on historical data using seasonal factors. The focus is on reducing logistics costs and inventories.

Stage 3: Integrate

The focus here is on integrating logistics into the overall supply chain. How logistics will affect customer service, procurement, and manufacturing is the main consideration. Productivity enhancements and cost reductions are achieved through connections to supply management and third-party logistics providers.

Stage 4: Collaborate

By this stage, logistics is an integrated part of a shared supply chain management vision. Planning involves not only the company's own departments, but also its partners — suppliers, manufacturers, and retailers. The focus is on improving end-to-end indicators (service level, profit, and costs throughout the chain) and creating additional value for the customer.

Stage 5: Orchestrate

The planning and execution processes are synchronized. For example, the company adjusts the level of safety stocks and the volume of raw material orders from the supplier when the demand for finished products changes. The focus is on process transparency and the reduction of reaction time to changes, such as a sudden change in demand or an increase in delivery time.

While implementing S&OP can be immensely valuable for the company’s processes and bottom line, it is not a requirement for every business. Organizations with complex supply chains and unpredictable demand are most likely to benefit from it but smaller companies may struggle to introduce such changes all at once.

As a starting point, businesses can focus on digitalizing their supply chains and making the most out of their supply chain operations. For both strategic and tactical supply chain planning, they can leverage supply chain modeling and optimization software, such as anyLogistix, as it combines the best of both worlds.

While many companies still turn to Excel spreadsheets when planning for their supply chains, this approach has limited application for solving complex business challenges. For deeper insights and more effective solutions, analytical optimization and dynamic simulation are among the most powerful tools for supply chain planning and management.

To learn more about optimization, simulation, and the way they’re combined in anyLogistix, read our white paper.